Home> Pre-heated Roll Forming

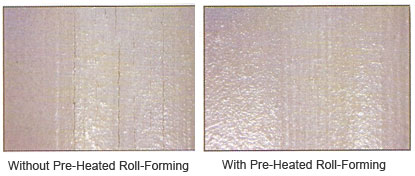

All manufacturing processes that form panels cause strain on the material in tension-bend areas, which can overstress the protective coatings and lead to the formation of fractures. These fractures, called micro-crazing, are only visible under strong magnification. These tiny cracks not only allow the elements sufficient access to the steel to initiate corrosion, but provide cavities that trap moisture, accelerating this corrosion. Sacrificial galvanic coatings help to prolong the panel's integrity, but once the zinc and other less noble metals are prematurely consumed due to micro-crazing, the steel is left without protection.

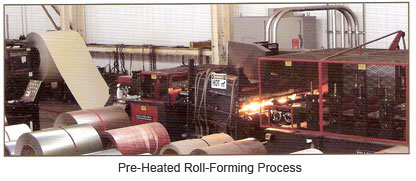

In order to enhance the lifespan of our product, North Star Metals exploits the benefits of pre-heating all roll-formed panels. Pre-heating increases the elasticity of not only the paint and primer, but the zinc alloys in the galvanic coating as well. This increase in elasticity allows coatings to maintain uniform adhesion throughout the roll-forming process. Having found the perfect temperature for roll forming, North Star is able to produce panels that are drastically less susceptible to micro-crazing and the inherent corrosion.